Page 50 from: West Coast report + Plastics Special

Steinert’s black plastics sorting technology closes

the gap between waste and new products

Black plastics represent a

particular recovery challenge

because they cannot be

detected with the optical

sorting technology found in

standard recycling plants.

However, Steinert technology

allows such plastics to be sorted

from the general waste stream

into pure grades.

This enables partners of the sorting specialist

to respond to the challenges of the circular

economy in a cost-effective manner and to be

equipped for all the processes involved in

plastic recovery and processing.

Near-infrared (NIR) technology is used in recy-

cling plants to identify which plastics can be

recovered. Typically, optical sensors use light

reflection to register the material and separate

it into its valuable fractions. However, the dark

colouring of black plastic packaging means

that light reflection is reduced to a minimum,

so the material cannot be correctly identified

or sorted by standard optical sensors.

256 MEASURING POINTS

Steinert has spent years working on detection

for such highly demanding sorting applica-

tions. The launch of the UniSort PR saw the

adoption of what is known as Hyper Spectral

Imaging (HSI) technology, which supersedes

the point-to-point scanners previously usually

used and, thanks to its finer resolution, covers

256 rather than the usual 16 measuring points

in the spectrum. It can evaluate even the

slightest differences in the chemical composi-

tion of the materials being processed.

In 2014, Steinert employed it UniSort Black tech-

nology to be the first company to be able to

detect and therefore positively sort black plas-

tics. This improved recycling rates and reduced

the residual fractions going to incineration.

In 2015, Steinert launched UniSort Film, a con-

veyor belt technology for high-performance

2D sorting at 4.5 metres per second. Together

with UniSort Black, this remains the only

machine available today for sorting black film.

At the same time, initial testing was underway

on UniSort BlackEye, the world’s first machine

for pure-grade detection and sorting of black

polyethylene (PE), polypropylene (PP). It has

been used around the globe since 2016.

UniSort BlackEye is the most recent iteration

of Steinert’s HSI technology, which it has been

consistently refining since 2011.

PURE-GRADE SEPARATION

Plastic-processing companies in particular can

benefit from Steinert products and replace

polymer granulates with mint-condition recy-

clates. Even black polyolefins (PO), which are

hard to recycle, can be sorted into fractions

such as PE, PP, polystyrene (PS) and acryloni-

trile butadiene styrene copolymers (ABS) to a

level of quality approaching primary plastics.

UniSort BlackEye allows plastic waste contain-

ing a high proportion of black to be separated

on an industrial scale. It can then to be upgrad-

ed to a plastic granulate with properties similar

to those of the primary raw material to be used

in the manufacture of durable, quality products.

This procedure means that, today, a significant

percentage of new plastics can be replaced

with recycled materials, thereby saving hun-

dreds of thousands of tons of CO2 every year.

GERMANY’S LARGEST SITE RELIES ON NIR

In addition to working with the plastic process-

ing industry, Steinert also provides disposal

companies with solutions for their sorting tasks

and combines it with over 130 years of process

know-how. For example, Steinert enables the

Germany’s largest approved single site for

post-consumer packaging to respond to tight-

er packaging legislation which came into force

at the start of the year and to increase the pro-

portion of pure-grade plastics which can be

recycled: ‘Our partnership with Steinert has

been intensive and the right resources were

put in place to affectively handle the challeng-

ing task we faced. We quickly achieved our

goals. We managed this by gathering together

our strengths and so achieved rapid progress,’

says Christian Hündgen, general manager at

Hündgen Entsorgung.

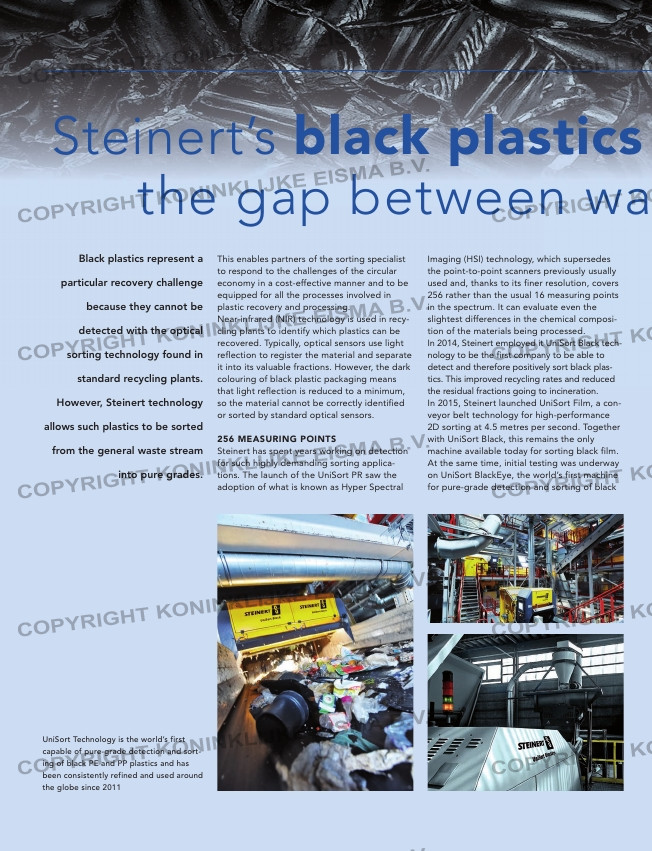

UniSort Technology is the world’s first

capable of pure-grade detection and sort-

ing of black PE and PP plastics and has

been consistently refined and used around

the globe since 2011

50-51_steinert.indd 50 08-08-19 11:15