Page 62 from: Recycling International July issue | 2021 + TOP 100!

62

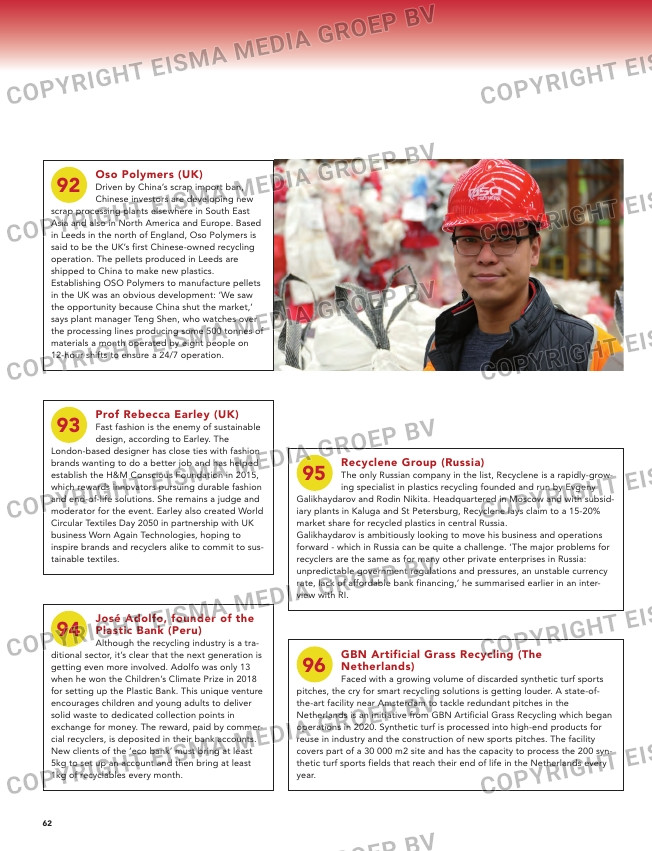

Oso Polymers (UK)

Driven by China’s scrap import ban,

Chinese investors are developing new

scrap processing plants elsewhere in South East

Asia and also in North America and Europe. Based

in Leeds in the north of England, Oso Polymers is

said to be the UK’s first Chinese-owned recycling

operation. The pellets produced in Leeds are

shipped to China to make new plastics.

Establishing OSO Polymers to manufacture pellets

in the UK was an obvious development: ‘We saw

the opportunity because China shut the market,’

says plant manager Teng Shen, who watches over

the processing lines producing some 500 tonnes of

materials a month operated by eight people on

12-hour shifts to ensure a 24/7 operation.

José Adolfo, founder of the

Plastic Bank (Peru)

Although the recycling industry is a tra-

ditional sector, it’s clear that the next generation is

getting even more involved. Adolfo was only 13

when he won the Children’s Climate Prize in 2018

for setting up the Plastic Bank. This unique venture

encourages children and young adults to deliver

solid waste to dedicated collection points in

exchange for money. The reward, paid by commer-

cial recyclers, is deposited in their bank accounts.

New clients of the ‘eco bank’ must bring at least

5kg to set up an account and then bring at least

1kg of recyclables every month.

GBN Artificial Grass Recycling (The

Netherlands)

Faced with a growing volume of discarded synthetic turf sports

pitches, the cry for smart recycling solutions is getting louder. A state-of-

the-art facility near Amsterdam to tackle redundant pitches in the

Netherlands is an initiative from GBN Artificial Grass Recycling which began

operations in 2020. Synthetic turf is processed into high-end products for

reuse in industry and the construction of new sports pitches. The facility

covers part of a 30 000 m2 site and has the capacity to process the 200 syn-

thetic turf sports fields that reach their end of life in the Netherlands every

year.

Prof Rebecca Earley (UK)

Fast fashion is the enemy of sustainable

design, according to Earley. The

London-based designer has close ties with fashion

brands wanting to do a better job and has helped

establish the H&M Conscious Foundation in 2015,

which rewards innovators pursuing durable fashion

and end-of-life solutions. She remains a judge and

moderator for the event. Earley also created World

Circular Textiles Day 2050 in partnership with UK

business Worn Again Technologies, hoping to

inspire brands and recyclers alike to commit to sus-

tainable textiles.

Recyclene Group (Russia)

The only Russian company in the list, Recyclene is a rapidly-grow-

ing specialist in plastics recycling founded and run by Evgeny

Galikhaydarov and Rodin Nikita. Headquartered in Moscow and with subsid-

iary plants in Kaluga and St Petersburg, Recyclene lays claim to a 15-20%

market share for recycled plastics in central Russia.

Galikhaydarov is ambitiously looking to move his business and operations

forward – which in Russia can be quite a challenge. ‘The major problems for

recyclers are the same as for many other private enterprises in Russia:

unpredictable government regulations and pressures, an unstable currency

rate, lack of affordable bank financing,’ he summarised earlier in an inter-

view with RI.

Jeffrey Spangenberger, founder of the Recell

Center (USA)

America will have a little shy of two million tonnes of depleted

electric vehicle batteries by 2040. ‘It’s clear the demand for electric car bat-

tery materials cannot be met without recycling,’ says Spangenberger,

researcher at the Argonne National Laboratory who has worked on several

projects to resolve the battery recycling issue. ‘The US is trailing other coun-

tries when it comes to battery recycling: we’re trying to pick up steam and

become a leader.’

As a result, Spangenberger helped establish the Recell Center in 2019, a

EUR 5 million cathode-to-cathode recycling initiative that strives to provide

stability to the battery supply chain. ‘If you can take out and fix a cathode

and put it back in a battery, that makes a lot more sense than recycling the

cathode into metal powder and getting back only a third to half the value of

the component.’

92

94

96

93

95

DGrade (UAE)

DGrade delivers closed-loop solutions with collected plastics

reused in the fabrication of clothing, uniforms and accessories for

customers across the UAE and beyond. One project is Simply Bottles which

connects schools and businesses to educate and boost plastic bottle recy-

cling in the UAE. Since its inception, the initiative has engaged hundreds of

thousands of students and employees, recovering more than 34 tonnes of

PET. DGrade also works with the Formula 1 Yas Marina Circuit to collect

plastic from the race and other events which is then recycled into uniforms

for staff at the circuit. A new UAE based facility will use flakes from PET bot-

tles in the production of yarn and new bottles.

24-25-26-27-28-29-30-31-32-33-34-36-37-38-39-40-41-45-46-47-48-49-50-51-52-53-54-55-56-57-58-59-60-61-62-63_top100.indd 62 08-07-21 08:57