Page 31 from: Recycling Technology 2016

31

2016

Research: LAMP PHOSPHOR WASTE

taining rare earths are made for these markets.

Two aspects of recycling must be addressed:

collection and also recycling technology. For

most products, collection is the biggest bot-

tleneck. The reuse of industrial manufactur-

ing scrap is therefore one of the first matters

to be considered but about which very little is

known because company production secrets

may be involved.

Recycling from end-of-life consumer

products requires a more elaborate collection

effort. Some car and air-conditioning manu-

facturers are considering the recovery of valu-

able neodymium-iron-boron magnets from

their end-of-life products, but the best collec-

tion rate at present is observed for fluorescent

lamps. In most Western countries, collection

of these lamps is mandatory and organised

by the government owing to the presence of

trace amounts of mercury. Most of the time,

however, the lamps are simply dismantled to

safely dispose of the mercury and sometimes

also recycle the glass, but nothing is done with

the rare-earth-containing phosphor powders.

Critical and less critical

These phosphor powders convert the ul-

traviolet light generated by the mercury in

the lamp into green, red and blue visible light,

which together are perceived as white light

by the human eye. These phosphors contain

significant amounts of the critical rare earths

yttrium, terbium and europium, as well as the

less critical lanthanum and cerium. Unfortu-

nately, the lamp phosphor waste also contains

large amounts of less valuable products such

as the broadband white halophosphate phos-

phor ‘HALO’, alumina and glass particles.

An overview of the phosphor powder

composition is given in the table accompa-

nying this feature. The most valuable compo-

nent by far is the red phosphor YOX, which

holds 80% of the rare earths and 70% of the

value in the lamp phosphor powder.

Waste and energy challenges

In 2012, Solvay launched a recycling op-

eration at La Rochelle in France for the an-

nual treatment of around 2000 tons of phos-

phor waste. The company’s patented process

is based on the total dissolution of the lamp

phosphor waste using a variety of acidic,

alkaline and high-temperature attacks. All

the elements are then separated by multiple-

stage solvent extraction to produce pure rare

earths. This process is very effective but is

relative long and therefore requires signifi-

cant amounts of chemicals and energy. Re-

searchers worldwide are therefore looking at

innovative ways to process this waste more

efficiently. There are two main technical chal-

lenges associated with the treatment of lamp

phosphor waste. The first is the unwanted

dissolution of the non-valuable HALO: this

phosphor is very easily dissolved in diluted

acidic solutions, and since it can make up al-

most 50% by weight of the waste, it leads to

substantial acid consumption and pollutes the

solution with unwanted elements, which in

turn generates waste.

The second challenge concerns the pro-

cessing of the very inert phosphors LAP, BAM

and CAT. These are currently subjected to a

high-temperature process called alkaline fu-

sion: a source of oxygen such as Na2O, NaOH

or Na2CO3 is mixed with the phosphor pow-

der and then heated at 700–1000 °C to con-

vert all the elements into oxides, which can

then be dissolved in nitric acid. This process

is quite energy-intensive and researchers are

therefore also looking at ways of significantly

reducing the required temperature.

Achieving selectivity

Recently, we published a front-cover ar-

ticle in the ‘Green Chemistry’ journal* out-

lining a new, patented recycling process that

addresses the unwanted dissolution of HALO.

In this process, the most valuable component

in the lamp phosphor powders, namely YOX,

is dissolved selectively and the phosphor can

be regenerated at the end of this three-step

process.

To achieve this selectivity, we used an ac-

id-functionalised ionic liquid called betain-

ium bistriflimide. Ionic liquids are organic

solvents which consist entirely of ions and

which are liquid below 100 °C. The fact that

they consist entirely of ions gives them some

unique properties such as negligible vapour

pressure (no evaporation), low flammability

and relatively low toxicity, especially com-

pared to other organic solvents. Ionic liquids

are also often considered designer solvents

owing to the endless different combinations

of anions and cations to form ionic liquids.

A specialised, task-specific ionic liquid

can therefore be designed for each particular

application in order to meet its requirements

in the best possible manner. The ionic liquid

used in our process contains betaine as cati-

on and a bistriflimide anion: betaine is used

worldwide as a food additive for animals and

bistriflimide anions are used as electrolyte

in lithium-ion batteries. The wide availabil-

ity of both components and the convenient

one-step synthesis of this ionic liquid ren-

der it relatively affordable to make, despite

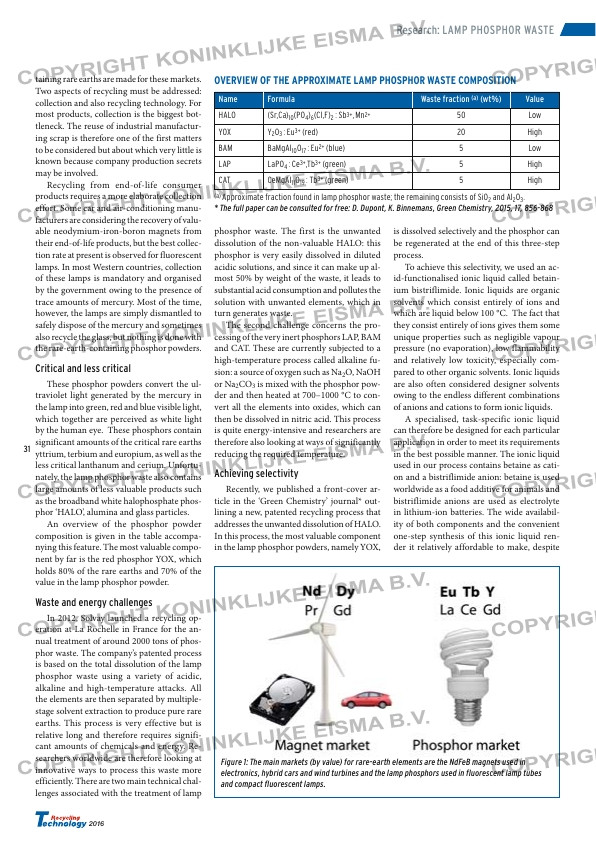

Figure 1: The main markets (by value) for rare-earth elements are the NdFeB magnets used in

electronics, hybrid cars and wind turbines and the lamp phosphors used in fluorescent lamp tubes

and compact fluorescent lamps.

OVERVIEW OF THE APPROXIMATE LAMP PHOSPHOR WASTE COMPOSITION

Name Formula Waste fraction (a) (wt%) Value

HALO (Sr,Ca)10(PO4)6(Cl,F)2 : Sb3+, Mn2+ 50 Low

YOX Y2O3 : Eu3+ (red) 20 High

BAM BaMgAl10O17 : Eu2+ (blue) 5 Low

LAP LaPO4 : Ce3+,Tb3+ (green) 5 High

CAT CeMgAl11O19 : Tb3+ (green) 5 High

(a) Approximate fraction found in lamp phosphor waste; the remaining consists of SiO2 and Al2O3.

* The full paper can be consulted for free: D. Dupont, K. Binnemans, Green Chemistry, 2015, 17, 856-868