Page 30 from: Recycling International November/December issue 2024

30

A U T H O R S Kirstin Linnenkoper, Martijn Reintjes

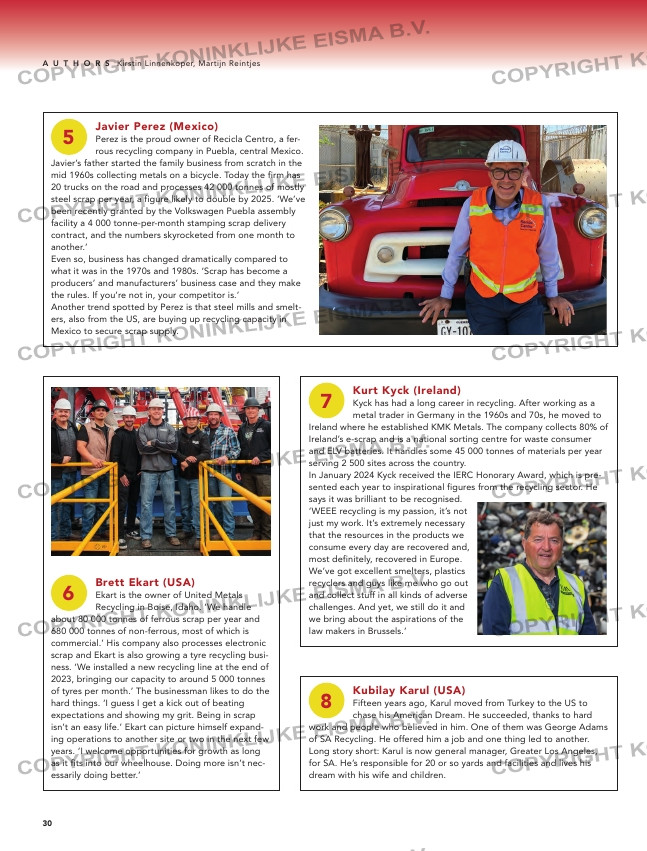

Javier Perez (Mexico)

Perez is the proud owner of Recicla Centro, a fer-

rous recycling company in Puebla, central Mexico.

Javier’s father started the family business from scratch in the

mid 1960s collecting metals on a bicycle. Today the firm has

20 trucks on the road and processes 42 000 tonnes of mostly

steel scrap per year, a figure likely to double by 2025. ‘We’ve

been recently granted by the Volkswagen Puebla assembly

facility a 4 000 tonne-per-month stamping scrap delivery

contract, and the numbers skyrocketed from one month to

another.’

Even so, business has changed dramatically compared to

what it was in the 1970s and 1980s. ‘Scrap has become a

producers’ and manufacturers’ business case and they make

the rules. If you’re not in, your competitor is.’

Another trend spotted by Perez is that steel mills and smelt-

ers, also from the US, are buying up recycling capacity in

Mexico to secure scrap supply.

5

Kurt Kyck (Ireland)

Kyck has had a long career in recycling. After working as a

metal trader in Germany in the 1960s and 70s, he moved to

Ireland where he established KMK Metals. The company collects 80% of

Ireland’s e-scrap and is a national sorting centre for waste consumer

and ELV batteries. It handles some 45 000 tonnes of materials per year

serving 2 500 sites across the country.

In January 2024 Kyck received the IERC Honorary Award, which is pre-

sented each year to inspirational figures from the recycling sector. He

says it was brilliant to be recognised.

‘WEEE recycling is my passion, it’s not

just my work. It’s extremely necessary

that the resources in the products we

consume every day are recovered and,

most definitely, recovered in Europe.

We’ve got excellent smelters, plastics

recyclers and guys like me who go out

and collect stuff in all kinds of adverse

challenges. And yet, we still do it and

we bring about the aspirations of the

law makers in Brussels.’

Kubilay Karul (USA)

Fifteen years ago, Karul moved from Turkey to the US to

chase his American Dream. He succeeded, thanks to hard

work and people who believed in him. One of them was George Adams

of SA Recycling. He offered him a job and one thing led to another.

Long story short: Karul is now general manager, Greater Los Angeles,

for SA. He’s responsible for 20 or so yards and facilities and lives his

dream with his wife and children.

Brett Ekart (USA)

Ekart is the owner of United Metals

Recycling in Boise, Idaho. ‘We handle

about 80 000 tonnes of ferrous scrap per year and

680 000 tonnes of non-ferrous, most of which is

commercial.’ His company also processes electronic

scrap and Ekart is also growing a tyre recycling busi-

ness. ‘We installed a new recycling line at the end of

2023, bringing our capacity to around 5 000 tonnes

of tyres per month.’ The businessman likes to do the

hard things. ‘I guess I get a kick out of beating

expectations and showing my grit. Being in scrap

isn’t an easy life.’ Ekart can picture himself expand-

ing operations to another site or two in the next few

years. ‘I welcome opportunities for growth as long

as it fits into our wheelhouse. Doing more isn’t nec-

essarily doing better.’

7

8

6

Chris Sheppard (UK)

Sheppard leads European Metal Recycling

(EMR) from its Warrington HQ. During the

last two decades as ceo, he has seen the company

expand to more than 120 sites worldwide, including

more than 60 facilities in the UK and 54 in the US. A

pilot wind turbine processing centre in Glasgow,

Scotland is part of the Re-Rewind R&D project, which is

largely funded by the UK Government. Sheppard is con-

fident this site is integral to establishing a circular sup-

ply chain for rare earth magnets used in wind turbines.

He expects the first ‘big wave’ of decommissioned tur-

bines to hit the market in 2027. Sheppard is also excited

about a new strategic

partnership with

Australian firm

Renewable Metals.

Together, they want to

tackle lithium-ion bat-

teries using an innova-

tive shredding and

refining technology. A

dedicated recycling

plant in Birmingham is

projected to open in

the first half of 2025.

Murat Özdemir (Turkey)

In rough market conditions, Turkey’s PET

recycler Başatli tries to keep its head above

water. ‘These are really uncertain and challenging times

for our industry, it is very difficult,’ says md Özdemir. If

someone asked him if it was wise to invest in plastics

recycling, his answer would be: ‘No. Put your money

into something else.’

Basatli has been talking to end users and big brands like

Coca-Cola, Nestle and Alpla. As long as virgin plastic is

cheaper, he says, they will keep using it instead of rPET.

‘For a recycler, it’s unacceptable and very frustrating to

see parts of our production standing still.’

Ever the optimist, Özdemir sees light at the end of the

tunnel because the Turkish government is actively pro-

moting recycling. ‘We’re kind of following the EU route

which means there will be more r+e-cycling rather than

less. What’s more, OEMs and big brands like Coca Cola

have committed to use 50% rPET in their packaging by

2030 which can only further boost our business and vol-

umes.’

28-48_top100.indd 30 21-11-2024 09:32