Page 12 from: Recycling International November/December issue 2024

12

THE MAN WHO INNOVATED TATA STEEL DIES

Ratan Tata, the Indian entrepreneur who transformed Tata Group into a

multi-billion-dollar conglomerate, has passed away at the age of 86.

Tata led the company for more than 20 years.

He took over the reins of Tata Group from his uncle in 1991, amid a power

struggle within the company’s leadership. Despite the internal challenges,

Ratan Tata unified the leadership and set out to modernise the company’s

image. His efforts paid off and in 2008 Business Week named Tata Group

one of the ten most innovative companies in the world.

Tata expanded the group significantly through international acquisitions,

turning it into a conglomerate with more than 100 subsidiaries. In the

Netherlands, Tata Group is best known for its 2007 acquisition of the

British-Dutch steel company Corus, a successor to Hoogovens. Today, Tata

Group remains the primary shareholder of Tata Steel in IJmuiden.

TSR WINS THREE-YEAR SUPPLY DEAL

WITH NOVELIS

TSR Recycling has struck as three-year agree-

ment with Novelis to provide approximately 75

000 tonnes of aluminium scrap to be processed

into low-carbon sheet for the automotive indus-

try.

TSR, part of the Remondis Group, processes 7.2

million tonnes ferrous and non-ferrous metals and

has 170 business locations with 4 500 employees

across Europe. The deal will see recycled alumini-

um delivered to what Novelis says is Europe’s larg-

est recycling centre at Nachterstedt in Saxony-

Anhalt, Germany.

MARKET DEMAND

Novelis says the strategic agreement directly sup-

ports rising market demand for high-recycled-con-

tent aluminium. Novelis is developing innovative

solutions with its automotive customers to absorb

more pre- and post-consumer scrap into new

alloys.

Denis Reuter, coo TSR Group says: ‘We are excited

to deepen our collaboration with Novelis based on

our joint purpose to maximize circularity and

decrease carbon emissions, conserve natural

resources and reduce energy of the material indus-

tries.

‘By working together, we can lead the transition

toward a circular economy for the automotive sec-

tor and beyond.’

WM SPREADS ITS ROOTS IN TEXAS

US recycler WM is constructing a new recycling

facility in Fort Worth, Texas. It believes the site will

boost recycling efforts across the north of the

state.

WM’s plant has been designed to treat around 145

000 tonnes of recyclables per year. The 10 500m

site is scheduled to begin operations by the end of

2025. It will include multiple lines of advanced optical

sorters.

WM says the expansion is part of the company’s US$ 1

billion (EUR 900 000 million) investment to update its

recycling facilities in the US between 2022 and 2026.

Meanwhile, WM recently acquired medical waste spe-

cialist Stericycle for US$ 7.2 billion. The recycler

believes the healthcare market offers long-term

growth in terms of scrap management.

Together, the partners aim to ‘unlock new opportuni-

ties’, according to Stericycle ceo Cindy Miller. She says

customers are looking to manage a greater volume

and variety of materials in a safe, responsible and sus-

tainable way.

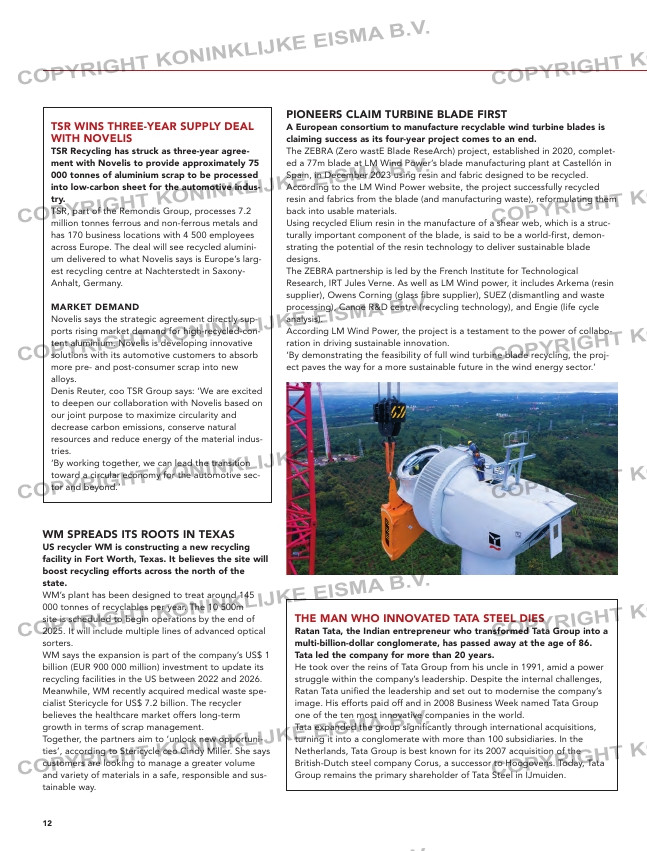

PIONEERS CLAIM TURBINE BLADE FIRST

A European consortium to manufacture recyclable wind turbine blades is

claiming success as its four-year project comes to an end.

The ZEBRA (Zero wastE Blade ReseArch) project, established in 2020, complet-

ed a 77m blade at LM Wind Power’s blade manufacturing plant at Castellón in

Spain, in December 2023 using resin and fabric designed to be recycled.

According to the LM Wind Power website, the project successfully recycled

resin and fabrics from the blade (and manufacturing waste), reformulating them

back into usable materials.

Using recycled Elium resin in the manufacture of a shear web, which is a struc-

turally important component of the blade, is said to be a world-first, demon-

strating the potential of the resin technology to deliver sustainable blade

designs.

The ZEBRA partnership is led by the French Institute for Technological

Research, IRT Jules Verne. As well as LM Wind power, it includes Arkema (resin

supplier), Owens Corning (glass fibre supplier), SUEZ (dismantling and waste

processing), Canoe R&D centre (recycling technology), and Engie (life cycle

analysis).

According LM Wind Power, the project is a testament to the power of collabo-

ration in driving sustainable innovation.

‘By demonstrating the feasibility of full wind turbine blade recycling, the proj-

ect paves the way for a more sustainable future in the wind energy sector.’

CALL TO ARMS FOR UK PLASTICS

RECYCLING

Recycling plastic targets in the UK are achievable with

increased investment, smarter legislation, and improved

communication and collection systems, according to the

national industry association.

The potential for greater recycling comes from the British

Plastics Federation (BPF) in an updated version of its

Recycling Roadmap which was first published in 2021. It

notes that many of the required changes mentioned then

have not happened. ‘This is due to delays in implementing

key policies as well as particularly challenging economic

circumstances,’ says the BPF.

Achieving a recycling rate of 69% by 2030 (as outlined in

the first edition) will take longer and requires urgent col-

lective action from the government and industry, as well as

support from the public, it argues.

The new edition urges more government investment in the

UK’s recycling infrastructure, for both mechanical and

chemical recycling. The forecast highlights that the amount

of material chemically recycled within the UK by 2030 is

200 000 tonnes lower than the first roadmap indicated. But

it notes that 400 000 tonnes of chemically recycled materi-

al is possible by 2035 if certain obstacles are overcome.

10-11-12-13_trendsupdatesiad.indd 12 21-11-2024 08:46