32

Energised SK tes ramps

up li-ion recycling

South Korean battery recycler SK tes opened a new facility in the Netherlands in

September 2024. According to the company, the port of Rotterdam is the ideal

place to take battery recycling in Europe to the next level.

closed loop for EV batteries to the

US-Mexico-Canada region by 2026.

IMPORTANT HUB

The company’s new factory in

Rotterdam focuses on the ‘young but

rapidly emerging’ market of EVs. For

Thomas Holberg, chief operating offi-

cer of the new facility, it is a ‘circular

investment’ with battery recycling

seen as essential for keeping pace

with increasing electrification.

‘For many years we have worked

closely with car manufacturers and

battery producers to understand their

needs and ensure that we remain at

the forefront of recycling technology,’

said Holberg during the official fes-

tive opening. A tour of the new recy-

cling ‘hub’ was a highlight of the

event.

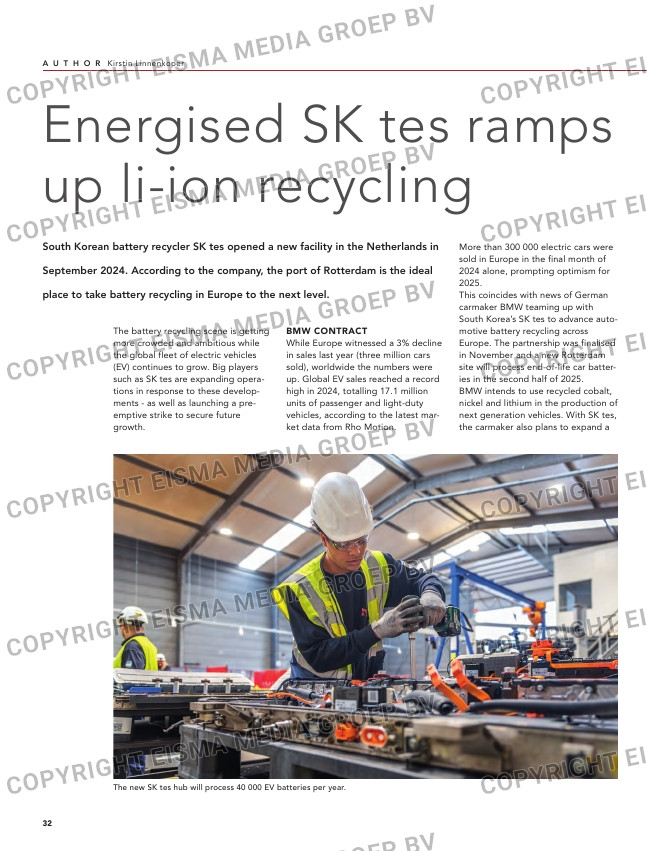

The site covers 10 000 square metres

and is equipped to process up to 10

000 tonnes of material annually –

which represents roughly 40 000 EV

batteries. Holberg adds plans are

underway to double the capacity by

The battery recycling scene is getting

more crowded and ambitious while

the global fleet of electric vehicles

(EV) continues to grow. Big players

such as SK tes are expanding opera-

tions in response to these develop-

ments – as well as launching a pre-

emptive strike to secure future

growth.

BMW CONTRACT

While Europe witnessed a 3% decline

in sales last year (three million cars

sold), worldwide the numbers were

up. Global EV sales reached a record

high in 2024, totalling 17.1 million

units of passenger and light-duty

vehicles, according to the latest mar-

ket data from Rho Motion.

More than 300 000 electric cars were

sold in Europe in the final month of

2024 alone, prompting optimism for

2025.

This coincides with news of German

carmaker BMW teaming up with

South Korea’s SK tes to advance auto-

motive battery recycling across

Europe. The partnership was finalised

in November and a new Rotterdam

site will process end-of-life car batter-

ies in the second half of 2025.

BMW intends to use recycled cobalt,

nickel and lithium in the production of

next generation vehicles. With SK tes,

the carmaker also plans to expand a

A U T H O R Kirstin Linnenkoper

The new SK tes hub will process 40 000 EV batteries per year. The recycler is mainly dealing with production waste at the moment.

32-33-34-35_sktes.indd 32 29-01-2025 11:26