Page 47 from: Recycling International September/October issue | 2022

TECHNOLOGY EXPERT

Applied Systems. ‘Our team can do an assess-

ment based on the scrap intake at a particular

site and advise on the economics and whether

the SpeedSorter makes sense for the customer.

We work closely with customers during the inte-

gration, setup, and commissioning phases of

each project, with service offerings to keep sys-

tems running long into the future.

THE SPEEDSORTER SYSTEM

A fully contained module that is dust-resistant

and rugged, SpeedSorter is designed to be inte-

grated into existing lines, or to be developed

easily within a production site by integrators.

Mounting the system is simple as only power

and communication lines are run to each unit.

SpeedSorter sends control signals to down-

stream hardware to direct diversion.

One of the hallmarks of the system is the simplic-

ity of the design with only a few moving parts.

This is a big advantage in the long run, as mov-

ing components are an obvious potential cause

of failure in real-world environments. The

straightforward design compared with competi-

tive systems allows SpeedSorter to be integrated

in a variety of environments with ease.

Additionally, the modular design makes the

entire sorting system redundant. For example, if

one of the sorting lines were to fail, additional

lines can continue to sort within the multi-sensor

system.

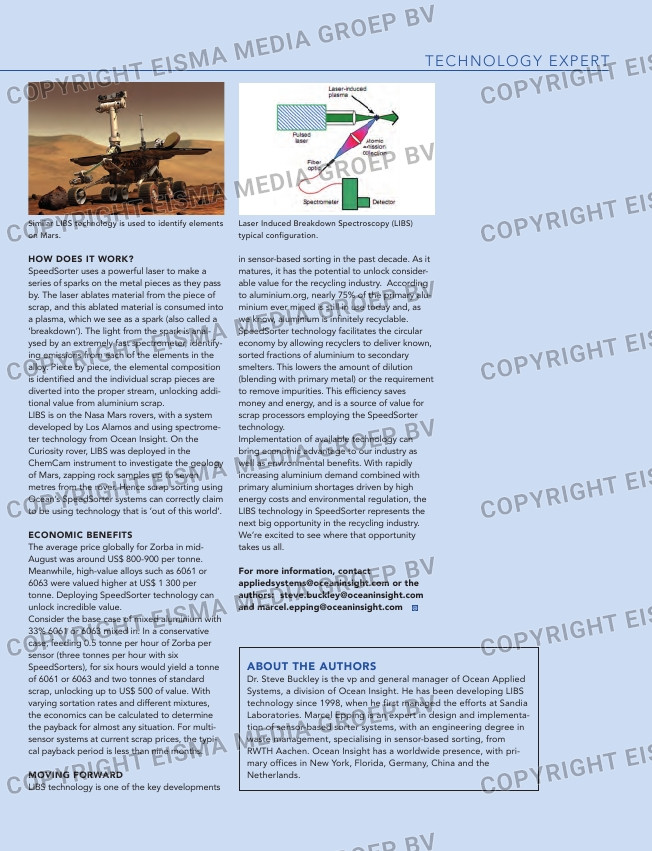

HOW DOES IT WORK?

SpeedSorter uses a powerful laser to make a

series of sparks on the metal pieces as they pass

by. The laser ablates material from the piece of

scrap, and this ablated material is consumed into

a plasma, which we see as a spark (also called a

‘breakdown’). The light from the spark is anal-

ysed by an extremely fast spectrometer, identify-

ing emissions from each of the elements in the

alloy. Piece by piece, the elemental composition

is identified and the individual scrap pieces are

diverted into the proper stream, unlocking addi-

tional value from aluminium scrap.

LIBS is on the Nasa Mars rovers, with a system

developed by Los Alamos and using spectrome-

ter technology from Ocean Insight. On the

Curiosity rover, LIBS was deployed in the

ChemCam instrument to investigate the geology

of Mars, zapping rock samples up to seven

metres from the rover. Hence scrap sorting using

Ocean’s SpeedSorter systems can correctly claim

to be using technology that is ‘out of this world’.

ECONOMIC BENEFITS

The average price globally for Zorba in mid-

August was around US$ 800-900 per tonne.

Meanwhile, high-value alloys such as 6061 or

6063 were valued higher at US$ 1 300 per

tonne. Deploying SpeedSorter technology can

unlock incredible value.

Consider the base case of mixed aluminium with

33% 6061 or 6063 mixed in. In a conservative

case, feeding 0.5 tonne per hour of Zorba per

sensor (three tonnes per hour with six

SpeedSorters), for six hours would yield a tonne

of 6061 or 6063 and two tonnes of standard

scrap, unlocking up to US$ 500 of value. With

varying sortation rates and different mixtures,

the economics can be calculated to determine

the payback for almost any situation. For multi-

sensor systems at current scrap prices, the typi-

cal payback period is less than nine months.

MOVING FORWARD

LIBS technology is one of the key developments

in sensor-based sorting in the past decade. As it

matures, it has the potential to unlock consider-

able value for the recycling industry. According

to aluminium.org, nearly 75% of the primary alu-

minium ever mined is still in use today and, as

we know, aluminium is infinitely recyclable.

SpeedSorter technology facilitates the circular

economy by allowing recyclers to deliver known,

sorted fractions of aluminium to secondary

smelters. This lowers the amount of dilution

(blending with primary metal) or the requirement

to remove impurities. This efficiency saves

money and energy, and is a source of value for

scrap processors employing the SpeedSorter

technology.

Implementation of available technology can

bring economic advantage to our industry as

well as environmental benefits. With rapidly

increasing aluminium demand combined with

primary aluminium shortages driven by high

energy costs and environmental regulation, the

LIBS technology in SpeedSorter represents the

next big opportunity in the recycling industry.

We’re excited to see where that opportunity

takes us all.

For more information, contact

[email protected] or the

authors: [email protected]

and [email protected]

ABOUT THE AUTHORS

Dr. Steve Buckley is the vp and general manager of Ocean Applied

Systems, a division of Ocean Insight. He has been developing LIBS

technology since 1998, when he first managed the efforts at Sandia

Laboratories. Marcel Epping is an expert in design and implementa-

tion of sensor-based sorter systems, with an engineering degree in

waste management, specialising in sensor-based sorting, from

RWTH Aachen. Ocean Insight has a worldwide presence, with pri-

mary offices in New York, Florida, Germany, China and the

Netherlands.

Laser Induced Breakdown Spectroscopy (LIBS)

typical configuration.

Designed for multi-sensor systems, the

SpeedSorter is often in 6 sensor sorting systems.

Similar LIBS technology is used to identify elements

on Mars.

46-47_oceaninsight.indd 47 12-09-2022 14:42