Page 59 from: May 2013

59May 2013

ensured. The material quality assurance, how-

ever, doesn’t end there. WorldScrap keeps track

of the yields obtained from the scrap shipped

by its World Recycling E-Market suppliers, and

uses them as the contractual benchmark for

future shipments of the same material. ‘People

must promise a recovery,’ Chen explains. If a

load diverges from past recoveries, that forms

the basis for a credit hit and an easy, binding

means to adjudicate a claim.

Those yards grow and shrink with their respec-

tive economies, but long term the trend is

towards growth. Already, Chen says, his yards

each trade 25 000 tonnes – and every last scrap

is sold via the World Recycling E-Market.

Meanwhile, the company is aggressively adding

suppliers to its online platform. For Chen, those

added suppliers aren’t just a guarantee of volume,

however; they also guarantee that the World

Recycling E-Market can be an international mar-

ket, and not just a China-oriented one. ‘I want

the protection so if Chinese demand is down,

perhaps Indian demand is up or US demand is

up,’ he explains. ‘We can have suppliers and buy-

ers in both places, and the scrap will still move.’

At the same time, Chen sees the trading plat-

form as a technology solution to a problem that

every growing scrap company faces: how to

manage the buying and selling of scrap in more

than one facility. ‘I planned this system because

I have too many yards for one person to check,’

he adds. Although it will always be difficult to

systematise scrap yard operations across a

geographically-diverse industry, the monitor-

ing systems in place as a result of the E-Market

allow Chen to supervise and standardise to a

degree that would otherwise be impossible.

Low-cost machines

However, that’s not the only way in which he is

systematising. His group also owns and oper-

ates Huilong Technology Developing Co. – a

technology development, manufacturing and

C o m p a n y p r o f i l e

In-house wire shredding system.

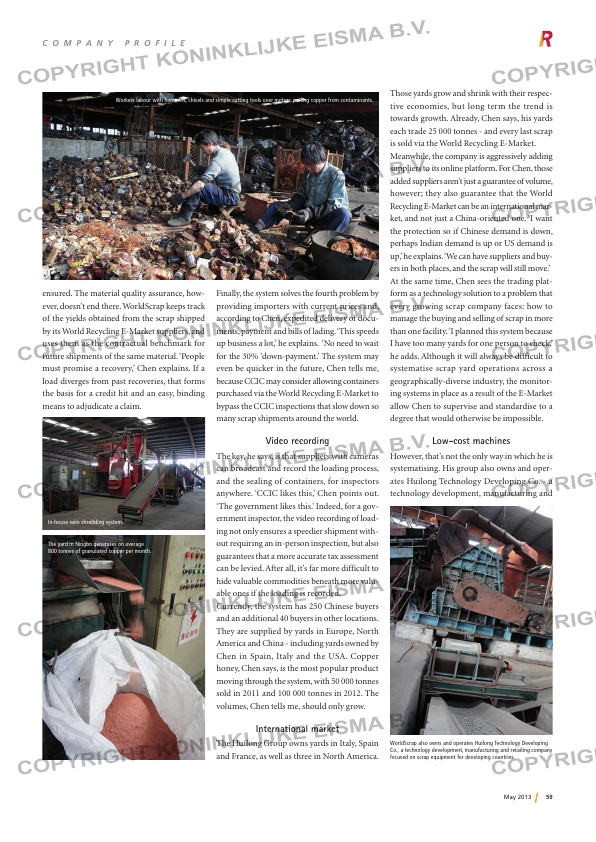

Workers labour with hammers, chisels and simple cutting tools over motors, pulling copper from contaminants.

The yard in Ningbo generates on average

800 tonnes of granulated copper per month.

WorldScrap also owns and operates Huilong Technology Developing

Co., a technology development, manufacturing and retailing company

focused on scrap equipment for developing countries.

Finally, the system solves the fourth problem by

providing importers with current prices and,

according to Chen, expedited delivery of docu-

ments, payment and bills of lading. ‘This speeds

up business a lot,’ he explains. ‘No need to wait

for the 30% ‘down-payment.’ The system may

even be quicker in the future, Chen tells me,

because CCIC may consider allowing containers

purchased via the World Recycling E-Market to

bypass the CCIC inspections that slow down so

many scrap shipments around the world.

Video recording

The key, he says, is that suppliers with cameras

can broadcast and record the loading process,

and the sealing of containers, for inspectors

anywhere. ‘CCIC likes this,’ Chen points out.

‘The government likes this.’ Indeed, for a gov-

ernment inspector, the video recording of load-

ing not only ensures a speedier shipment with-

out requiring an in-person inspection, but also

guarantees that a more accurate tax assessment

can be levied. After all, it’s far more difficult to

hide valuable commodities beneath more valu-

able ones if the loading is recorded.

Currently, the system has 250 Chinese buyers

and an additional 40 buyers in other locations.

They are supplied by yards in Europe, North

America and China – including yards owned by

Chen in Spain, Italy and the USA. Copper

honey, Chen says, is the most popular product

moving through the system, with 50 000 tonnes

sold in 2011 and 100 000 tonnes in 2012. The

volumes, Chen tells me, should only grow.

International market

The Huilong Group owns yards in Italy, Spain

and France, as well as three in North America.

RI-4_CompProfile.indd 59 06-05-13 14:24