Page 22 from: April 2013

Today, scarce metals make the world go round more than ever before. Life in the 21st cen-

tury wouldn’t be the same without scarce ele-

ments. Cell phones, iPads, lap-tops, televisions,

wind turbines, solar cells and many more prod-

ucts depend on these metals to function.

And that’s not to mention hybrid cars. ‘In fact,

mobility has become the major end-use for some

metals,’ Dr Christina Meskers told some 220

attendees of the latest International Automobile

Recycling Congress (IARC), held at La Hulpe

near Brussels. After all, it is scarce metals in bat-

teries and motors that keep electric vehicles roll-

ing and which, in catalytic converters, clean up

cars’ exhaust gases. It is meanwhile common

knowledge that the rising demand for these met-

als increases the risk of a bottleneck in supply. But

there is a way to escape this problem: by extract-

ing the metals from rolling raw material stores.

We only have to do this better than we have done

hitherto, it was suggested at the congress.

High Demand

In clean-tech cars of today, scarce metals are

essential. Demand from the automotive sector

is indeed very high for many metals that are con-

sidered as ‘critical’ or ‘scarce’ by governments

from a long-term perspective. Dr Meskers, who

received her MSc and PhD in metallurgical engi-

neering from the Netherlands’ Delft University

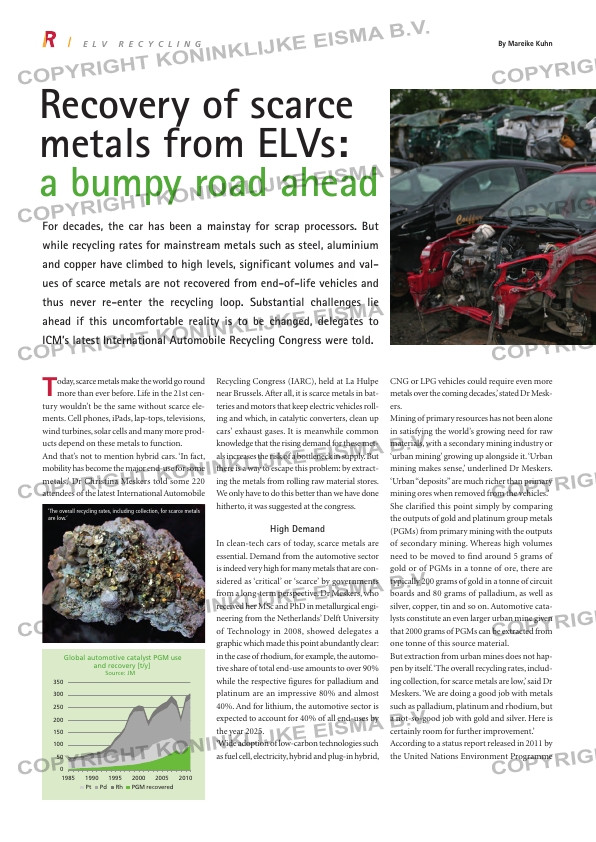

of Technology in 2008, showed delegates a

graphic which made this point abundantly clear:

in the case of rhodium, for example, the automo-

tive share of total end-use amounts to over 90%

while the respective figures for palladium and

platinum are an impressive 80% and almost

40%. And for lithium, the automotive sector is

expected to account for 40% of all end-uses by

the year 2025.

‘Wide adoption of low-carbon technologies such

as fuel cell, electricity, hybrid and plug-in hybrid,

CNG or LPG vehicles could require even more

metals over the coming decades,’ stated Dr Mesk-

ers.

Mining of primary resources has not been alone

in satisfying the world’s growing need for raw

materials, with a secondary mining industry or

‘urban mining’ growing up alongside it. ‘Urban

mining makes sense,’ underlined Dr Meskers.

‘Urban “deposits” are much richer than primary

mining ores when removed from the vehicles.’

She clarified this point simply by comparing

the outputs of gold and platinum group metals

(PGMs) from primary mining with the outputs

of secondary mining. Whereas high volumes

need to be moved to find around 5 grams of

gold or of PGMs in a tonne of ore, there are

typically 200 grams of gold in a tonne of circuit

boards and 80 grams of palladium, as well as

silver, copper, tin and so on. Automotive cata-

lysts constitute an even larger urban mine given

that 2000 grams of PGMs can be extracted from

one tonne of this source material.

But extraction from urban mines does not hap-

pen by itself. ‘The overall recycling rates, includ-

ing collection, for scarce metals are low,’ said Dr

Meskers. ‘We are doing a good job with metals

such as palladium, platinum and rhodium, but

a not-so-good job with gold and silver. Here is

certainly room for further improvement.’

According to a status report released in 2011 by

the United Nations Environment Programme

E L V r E c y c L i n g By Mareike Kuhn

For decades, the car has been a mainstay for scrap processors. But

while recycling rates for mainstream metals such as steel, aluminium

and copper have climbed to high levels, significant volumes and val-

ues of scarce metals are not recovered from end-of-life vehicles and

thus never re-enter the recycling loop. Substantial challenges lie

ahead if this uncomfortable reality is to be changed, delegates to

ICM’s latest International Automobile Recycling Congress were told.

Recovery of scarce

metals from ELVs:

a bumpy road ahead

0% 20% 40% 60% 80% 100%

Rh

Pd

Pb

Pt

REE

Al

Li

Car electronics and aux. motors not quantified (contain additional Pd & REE)

Share of automotive use in total end-use for some key automotive metals

2025

Sources: Pt, Pd, Rh (Johnson Matthey, 2011); Pb (ILZSG, 2011); REE (Du, 2011), Li (Signum Box, 2011)

0

50

100

150

200

250

300

350

1985 1990 1995 2000 2005 2010

Pt Pd Rh PGM recovered

Global automotive catalyst PGM use

and recovery [t/y]

Source: JM

Residues

Residues

Dissipation

Residues

Residues

Historic wastes

(tailings, landfills)

End-of-Life

Product

manufacture

Use

Natural resources

Metals, alloys& compounds

New

scrap

Raw materials production

Recyc

ling

from

industrial

materials

from

Concentrates

& ores

product

reuse

Based on: C.E.M. Meskers:

Coated magnesium, designed for sustainability?

PhD thesis Delft University of Technology, 2008

‘The overall recycling rates, including collection, for scarce metals

are low.’

RI-3_Automobile Recycling.indd 22 08-04-13 16:10