Page 61 from: April 2008

usage and sophistication in steel products, more and

more non-ferrous metals and non-metallics are being

used along with steel. As a result, when such com-

modities are scrapped, it is often difficult to separate

the metallics from the non metallics. Impurities such

as copper and tin cannot always be completely segre-

gated during scrap handling processes and so carry

over to the steelmaking stage. At the same time,

these impurities cannot be removed to any apprecia-

ble degree in any method of steelmaking.

Sharp scrap price fluctuations have also limited

its use in steelmaking.

DRI as a feedstock for steelmaking

DRI is produced via gas-based and coal-based

routes, with the former accounting for around 80%

of global output. Although production via the coal-

based route – which has been adopted mainly in

India – almost doubled from 10.2 million tonnes in

2003 to 19.7 million tonnes in 2006, its overall con-

tribution is still below 20%.

In India, the emergence of coal-based DRI pro-

duction has been significant in recent years. Here,

DRI production has witnessed an explosion from

only 200 000 tonnes in 1989-90 to 16.27 million

tonnes in 2006-07 (see Table 3).

At this stage, it is important to point out that DRI

contains at most 94% Fe – the remainder is gangue –

while scrap is approximately 100% Fe. On the posi-

tive side, the sulphur and phosphorus contents of

DRI are significantly lower than those of scrap,

while DRI is also devoid of any harmful residuals.

Indeed, one of the major advantages of DRI over

scrap is the total absence of tramp elements. For the

production of high-quality steel grades, where resid-

uals must be limited to a very narrow range, the use

of DRI/HBI has become a must. In this situation, the

amount of DRI/HBI used in place of scrap becomes

independent of the DRI/HBI price relative to scrap.

Its use is dictated purely by quality considerations.

Advantages of DRI

Where DRI is used in place of scrap, the following

advantages can accrue:

* Charging of DRI into EAFs in substantial quanti-

ties is possible by installing a system of continu-

ous charging. Good ‘flowability’ of DRI enables

continuous charging during heat making using an

over-head hopper. This is not possible with scrap.

* Although DRI from the coal-based route has a

maximum carbon content of 0.15%, gas-based DRI

can have carbon contents as high as 2-3% – offering

a distinct advantage over scrap in the case of high-

quality products such as ball bearing steel.

* High-carbon DRI not only helps in process control

during steelmaking, but it also carries chemical

energy which helps to reduce electrical power

consumption.

* DRI is a virgin product of stable quality whereas

scrap is more variable in its analysis.

* Mechanical shocks can occur on the bottom lining

when large pieces of scrap are charged to a furnace

but this problem is eliminated when using DRI.

* The lower sulphur content of DRI makes it a pre-

ferred coolant in the production of electrical steel

sheet, ball bearing steel, deep drawing steels, etc.

* Besides steelmaking, DRI can also be used in

blast furnace ironmaking to beneficial effect.

* Use of DRI in blast furnaces reduces the fuel rate

substantially, with resultant increases in pro-

ductivity.

Matters of concern

Hot metal and scrap have traditionally been the

major feed materials used in steelmaking. However,

over the years, hot metal production has been on a

steady decline, essentially because of problems

associated with coke supply and production. One of

the major advantages of steel is that it is infinitely

recyclable. As a result, today’s steel becomes tomor-

row’s scrap.

However, scrap quality and availability are now

matters of concern. Finding scrap to meet the strin-

gent requirements of today’s quality steel cus-

tomers is becoming increasingly difficult.

These factors have triggered interest in direct

reduction, with ‘manufactured scrap’ in the form of

DRI gaining ground as a complement to scrap. The

major advantages of DRI over scrap include its con-

trolled size, known composition and total absence of

tramp elements. These attributes make DRI an ide-

al feedstock for the production of high-quality steels

in electric arc furnaces.

S C R A P & D R I

Recycling International • April 2008 61

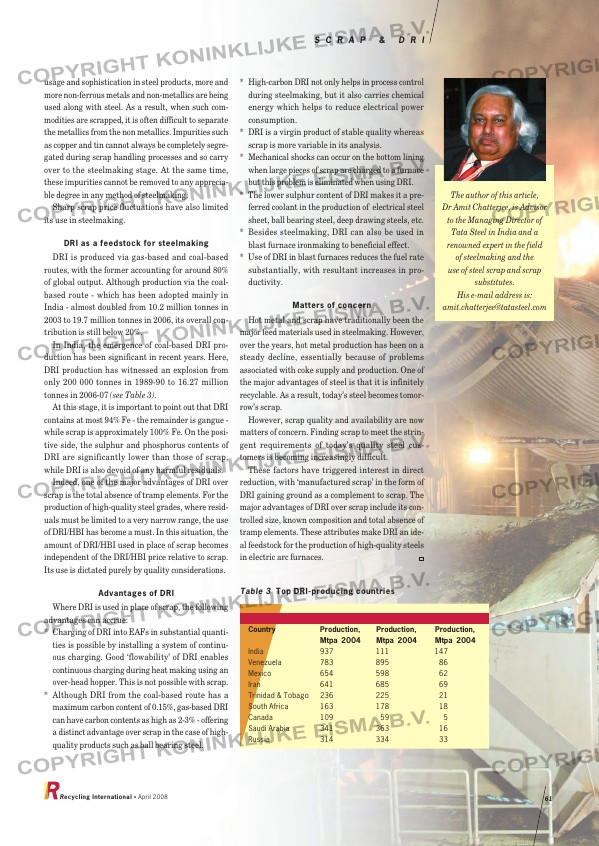

The author of this article,

Dr Amit Chatterjee, is Advisor

to the Managing Director of

Tata Steel in India and a

renowned expert in the field

of steelmaking and the

use of steel scrap and scrap

substitutes.

His e-mail address is:

[email protected]

Table 3 Top DRI-producing countries

Country Production, Production, Production,

Mtpa 2004 Mtpa 2004 Mtpa 2004

India 937 111 147

Venezuela 783 895 86

Mexico 654 598 62

Iran 641 685 69

Trinidad & Tobago 236 225 21

South Africa 163 178 18

Canada 109 59 5

Saudi Arabia 341 363 16

Russia 314 334 33

RI_044 Scrap & DRI:Opmaak 1 03-04-2008 15:27 Pagina 61