Page 37 from: April 2008

Owing to the market potential and low labour costs,

many companies have started to remanufacture

motor parts, with some factories concentrating on

electro motors. A secondary part such as this would

generally command one third to one half of the price

of a new one.

Hybrid cars

In the USA, car manufacturers General Motors,

Chrysler and Ford are also researching the best

way to recycle. On average, 84% of a vehicle is

recovered, primarily in the form of ferrous and non-

ferrous metals. ‘When you look to the manufactur-

ing side of our cars, over the past 30 years we were

able to make our cars a lot cleaner; the amounts of

NOx, CO and HC are almost 100% minimised com-

pared to the 1960s and 1970s,’ said Dr Candace

Wheeler, General Motors’ engineering representa-

tive. She participates in the Cooperative Research

and Development Agreement (CRADA) with the

American Plastics Council and US Department of

Energy’s Argonne National Laboratory, which con-

ducts research into best recycling practices. In addi-

tion to General Motors, the CRADA initiative

attracts representatives from Chrysler and Ford.

According to US research body J D Power, a total

of 345 000 hybrid cars were sold in the USA last year

thanks to climbing oil prices. This total compares to

the 256 000 sold in 2006. Mrs Wheeler observed:

‘Currently, most production auxiliary batteries are

nickel metal hydride, but the industry is moving to

lithium ion applications.’ The highest form of recy-

cling is reuse of the parts, she acknowledged, but

that depends on factors like ease of disassembly and

market demand for use in repair or replacement.

The second highest form of recycling is the remanu-

facturing of parts, which involves replacement of

specific, deteriorated components of parts with parts

meeting original OEM specifications.

The recycling method depends on several factors:

the technology available to process the material; the

existence of a supporting infrastructure; the cost of

virgin material; the ability to separate the materi-

als; the hazardous materials content; and the eco-

nomic value of the material.

She told delegates in Munich that the composi-

tion and configuration of the lithium-ion battery is

still in flux: ‘The chemistry is not finalised and the

configuration of battery packs is also not ready; to

be specific on this, some battery packs include elec-

tronics while some do not. Recycling infrastructures

for the lead-acid battery are well-defined, but the

advanced vehicle battery recycling infrastructure

is still in the process of being created.’

C A R R E C Y C L I N G

Recycling International • April 2008 37

Chinese pilot scheme for auto parts recovery

China has launched a pilot scheme to recover and reuse discarded auto parts. The

country is looking to boost the volume of auto parts that are reprocessed as well as to

spur innovation in recovering and rebuilding parts.

To date, three vehicle makers and 11 auto parts manufacturers have signed letters

of commitment to the recycling programme, according to the China state news agency

Xinhua. The recycling effort will focus initially on only a few products, including

engines, transmissions and electrical generators. Estimates put the cost of recycled

parts at around 60% that of new ones, China Central Television reports.

At the official opening of the scheme, the Deputy Head of the nation’s top economic

planner Xie Zhenhua said that China scraps more than 3 million motor vehicles each

year and that making good use of renewable resources within the scrapped vehicles is a

major task for the country’s car industry in order to achieve sustainable development.

According to Dong Yang, an expert in auto parts recovery with the China

Association of Automobile Manufacturers, China produced 8.88 million motor vehicles

in 2007 and is expected to take 4 million vehicles out of service each year starting

from 2010. That same year, the domestic market for auto parts is expected to grow to

Yuan 65 billion (US$ 9.2 billion), of which Yuan 3.8 billion (US$ 538 million) comprises

recovered parts which are currently valued at only Yuan 700 million (US$ 99 million).

The outcome of the BMW Recycling Trial

Material fraction Recycling Recovery Reuse Disposal

(products) (%) (%) (%) (%)

Pre-treatment and dismantling 4,78 1,66 8,70 –

Metals directly recyclable 62,55 – – –

Metal-containing composites 1,83 – – 1,88

Secondary fuel products – 8,03 – –

Plastics, products with

high plastic content 4,53 – – 4,15

Disposal products – – – 1,98

Total 73,69 9,69 8,70 8,01

(78,09) (10,27) (9,23) (8,47)

Back up samples 0,08

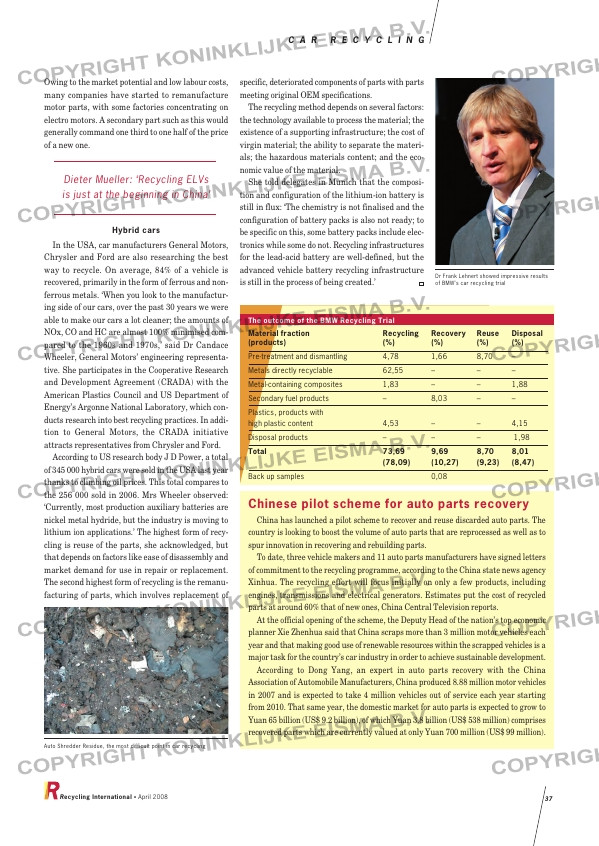

Dr Frank Lehnert showed impressive results

of BMW’s car recycling trial

Auto Shredder Residue, the most difficult point in car recycling

Dieter Mueller: ‘Recycling ELVs

is just at the beginning in China’

RI_028 (IARC) Car recycling:Opmaak 1 03-04-2008 15:18 Pagina 37