Page 66 from: Recycling International November/December issue 2024

66

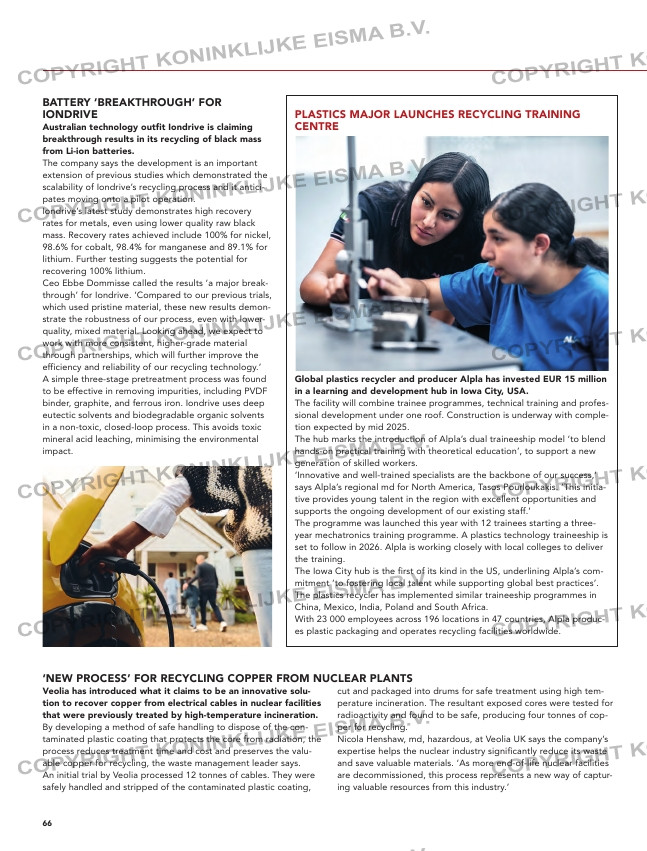

PLASTICS MAJOR LAUNCHES RECYCLING TRAINING

CENTRE

Global plastics recycler and producer Alpla has invested EUR 15 million

in a learning and development hub in Iowa City, USA.

The facility will combine trainee programmes, technical training and profes-

sional development under one roof. Construction is underway with comple-

tion expected by mid 2025.

The hub marks the introduction of Alpla’s dual traineeship model ‘to blend

hands-on practical training with theoretical education’, to support a new

generation of skilled workers.

‘Innovative and well-trained specialists are the backbone of our success,’

says Alpla’s regional md for North America, Tasos Pourloukakis. ‘This initia-

tive provides young talent in the region with excellent opportunities and

supports the ongoing development of our existing staff.’

The programme was launched this year with 12 trainees starting a three-

year mechatronics training programme. A plastics technology traineeship is

set to follow in 2026. Alpla is working closely with local colleges to deliver

the training.

The Iowa City hub is the first of its kind in the US, underlining Alpla’s com-

mitment ‘to fostering local talent while supporting global best practices’.

The plastics recycler has implemented similar traineeship programmes in

China, Mexico, India, Poland and South Africa.

With 23 000 employees across 196 locations in 47 countries, Alpla produc-

es plastic packaging and operates recycling facilities worldwide.

‘NEW PROCESS’ FOR RECYCLING COPPER FROM NUCLEAR PLANTS

Veolia has introduced what it claims to be an innovative solu-

tion to recover copper from electrical cables in nuclear facilities

that were previously treated by high-temperature incineration.

By developing a method of safe handling to dispose of the con-

taminated plastic coating that protects the core from radiation, the

process reduces treatment time and cost and preserves the valu-

able copper for recycling, the waste management leader says.

An initial trial by Veolia processed 12 tonnes of cables. They were

safely handled and stripped of the contaminated plastic coating,

cut and packaged into drums for safe treatment using high tem-

perature incineration. The resultant exposed cores were tested for

radioactivity and found to be safe, producing four tonnes of cop-

per for recycling.

Nicola Henshaw, md, hazardous, at Veolia UK says the company’s

expertise helps the nuclear industry significantly reduce its waste

and save valuable materials. ‘As more end-of-life nuclear facilities

are decommissioned, this process represents a new way of captur-

ing valuable resources from this industry.’

BATTERY ‘BREAKTHROUGH’ FOR

IONDRIVE

Australian technology outfit Iondrive is claiming

breakthrough results in its recycling of black mass

from Li-ion batteries.

The company says the development is an important

extension of previous studies which demonstrated the

scalability of Iondrive’s recycling process and it antici-

pates moving onto a pilot operation.

Iondrive’s latest study demonstrates high recovery

rates for metals, even using lower quality raw black

mass. Recovery rates achieved include 100% for nickel,

98.6% for cobalt, 98.4% for manganese and 89.1% for

lithium. Further testing suggests the potential for

recovering 100% lithium.

Ceo Ebbe Dommisse called the results ‘a major break-

through’ for Iondrive. ‘Compared to our previous trials,

which used pristine material, these new results demon-

strate the robustness of our process, even with lower-

quality, mixed material. Looking ahead, we expect to

work with more consistent, higher-grade material

through partnerships, which will further improve the

efficiency and reliability of our recycling technology.’

A simple three-stage pretreatment process was found

to be effective in removing impurities, including PVDF

binder, graphite, and ferrous iron. Iondrive uses deep

eutectic solvents and biodegradable organic solvents

in a non-toxic, closed-loop process. This avoids toxic

mineral acid leaching, minimising the environmental

impact.

Lindemann Satom 60x60xV Baler

Fully refurbished. Can be tested and

is immediately available.

[email protected]+44 1656 662641

CONTACT US NOW

Used Leimbach HS900 Side

Compression Shear

Comes with Pumphouse and is available ex site.

Check out our website for details.

www.engserve.com

NZ DRIVES FIRST NATIONAL TYRE RECYCLING SCHEME

New Zealand has launched Tyrewise, the country’s first national

tyre recycling scheme.

Tyrewise, a regulated product stewardship scheme, is seen as a

solution to a long-standing issue. A fee to fund the scheme has

been built into the cost of imported tyres that have entered the

market since 1 March.

Businesses including tyre shops can now call on free collection ser-

vices which launched in September. Members of the public can

take up to five used tyres a day to public collection sites around

the country, also at no cost.

The scheme covers all pneumatic and solid tyres for use on cars,

trucks, buses, motorcycles, aircraft, trailers and off-road vehicles.

Tyres for most agricultural machinery are also included. Bicycle tyres,

tyres for non-motorised equipment such as prams, and pre-cured

rubber for retreads will be included in the scheme at a future date.

INCENTIVISE

Tyrewise uses the producer fees to incentivise the conversion of end-

of-life tyres into an intermediary product for the domestic market.

‘New Zealand doesn’t have a great record on recovering and recy-

cling tyres,’ says Adele Rose, of Tyrewise Scheme Managers 3R

Group. ‘Of the 6.5 million which reach the end of their life each

year, only about 40% are being recycled – that will change with

Tyrewise.’

64-65-66-67_trendsupdatesiiad.indd 66 21-11-2024 08:46