Page 28 from: September 2007

Recycling International • September 2007 28

S O U T H A F R I C A

BEE scorecard

Black economic empowerment is driven by legis-

lation and regulation. An integral part of the BEE

Act is the balanced scorecard, which measures com-

panies’ empowerment progress in four areas.

This scorecard is defined and elaborated in the

recently-released BEE codes of good practice, which

will soon be passed into law. These codes will be bind-

ing on all state bodies and public companies, and the

government will look to do business with a BEE com-

pany when making economic decisions on: procure-

ment, licensing and concessions, public-private part-

nerships, and the sale of state-owned assets or busi-

nesses. Private companies must apply the codes if

they want to do business with any government enter-

prise or organ of state – that is, to tender for business,

apply for licences and concessions, enter into public-

private partnerships, or buy state-owned assets.

Currently, an estimated 20% of South Africa’s

scrap companies are BEE compliant.

The Reclamation Group

The Reclamation Group (Reclam) is South

Africa’s largest and only nationwide scrap and

waste processing company. The privately-held firm

was founded in 1998 as a merger of 15 family-

owned businesses.

Reclam’s business revolves around the purchas-

ing, processing and sale of ferrous and non-ferrous

scrap metals. Operating 60 facilities and boasting

2300 employees, the company is still based largely

in South Africa, although branches have been

opened in Mozambique, Swaziland, Malawi, Kenya,

Zambia and Botswana.

Having assembled a network of steel scrap recy-

cling centres throughout South Africa, the company

expanded some seven years ago into other recy-

clable commodities – such as glass, paper, card-

board and rubber – and into integrated waste man-

agement services, thus providing a one-stop waste

management/recycling solution. Reclam also oper-

ates a chemical plant for copper sulphates and an

aluminium ingot remelting plant.

Looking to the future, Reclam aims to extend its

interests in these ‘new’ commodities. ‘We especially

want to grow in paper and cardboard,’ says CEO

Martin van Wijngaarden. ‘Prices of these materi-

als have been plummeting over recent years and

we already export considerable volumes, mostly to

Asia. Reclam’s philosophy is always to serve the

domestic markets first and export the surplus

material.’

www.reclam.co.za

Cronimet RSA

Cronimet RSA is unique in South African terms in that it is the only recycling company

with a 100% focus on stainless steel and related alloys.

The country is home to only one stainless steel producer – Middelburg-based Columbus.

Cronimet sells most of its stainless steel scrap to Columbus as well as to local foundries. The

surplus is exported worldwide; the cobalt, tungsten and molybden alloyed material mainly to

Germany, the UK and Sweden.

Cronimet started its operations in South Africa in 1995. The plant at Alrode, near Durban,

is run by a local workforce headed by Alan Shunn and Bernard Maguire, who is currently also

the Chairman of the Metal Recyclers Association of South Africa (MRA). For information, vis-

it: www.mra.co.za. He observes: ‘We source our material almost exclusively from engineering

companies and scrap reverters such as oil refiners and mining companies in and around

Johannesburg as well as from scrap merchants, although we also buy material from neigh-

bouring African countries. To get the material to Alrode, we have our own fleet of transport

trucks.’

Cronimet currently collects around 2400 tonnes per month of ferritic, magnetic and other

grades of stainless steel scrap. In terms of processing, the company uses balers, croppers, and

torch cutting after manual sorting using portable analysers.

www.cronimet.com

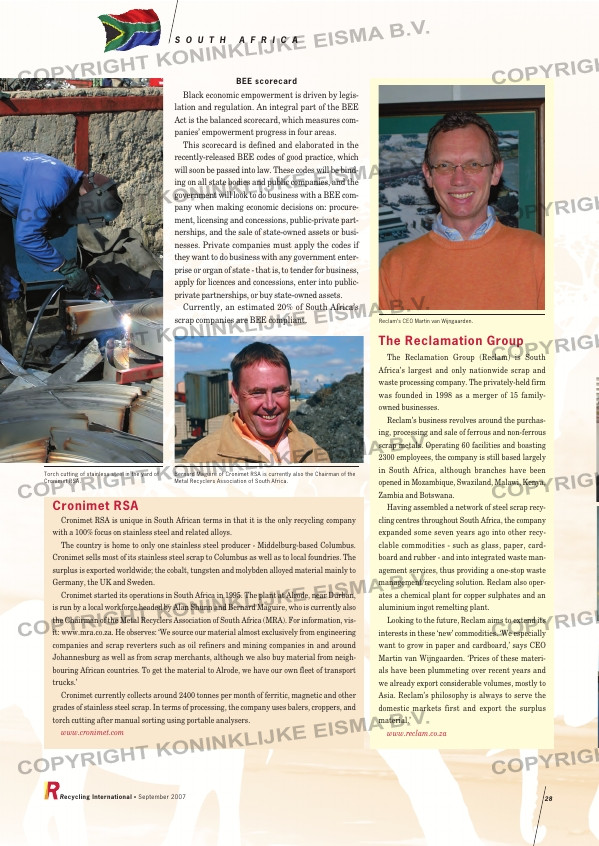

Reclam’s CEO Martin van Wijngaarden.

Bernard Maguire of Cronimet RSA is currently also the Chairman of the

Metal Recyclers Association of South Africa.

Torch cutting of stainless steel in the yard of

Cronimet RSA.

RI_038 South Africa_ingekort:Opmaak 1 07-09-2007 15:36 Pagina 28