Page 27 from: January / February 2014

27January/February 2014

Certainly not an everyday job

Dismantling a cargo plane is easier than taking apart a

passenger aircraft as ‘there are no seats, windows or

other non-metals which have to be separated from the

metals’, points out Galloo managing director Jan

Vandeputte. The Belgian recycling giant makes this

observation in light of its project to scrap two Boeing

747-type heavyweights.

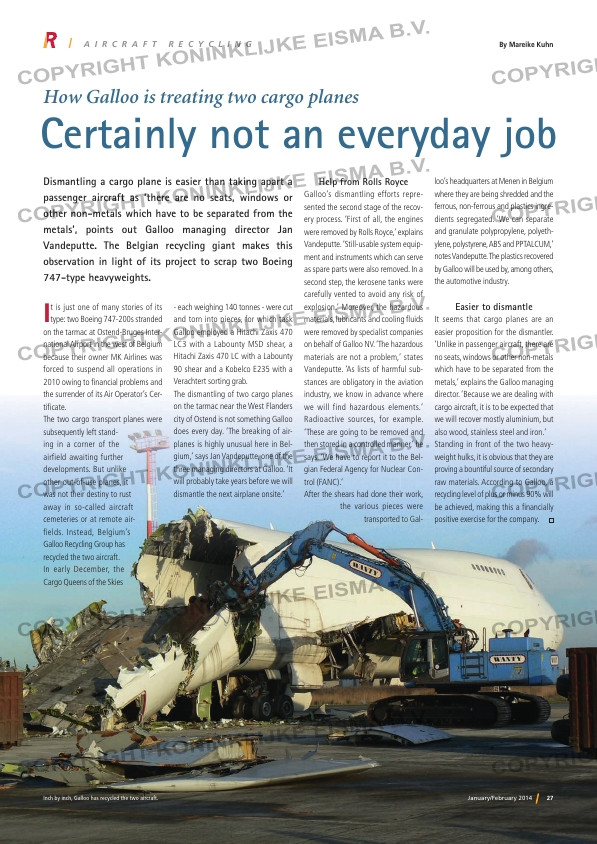

It is just one of many stories of its type: two Boeing 747-200s stranded

on the tarmac at Ostend-Bruges Inter-

national Airport in the west of Belgium

because their owner MK Airlines was

forced to suspend all operations in

2010 owing to fi nancial problems and

the surrender of its Air Operator’s Cer-

tifi cate.

The two cargo transport planes were

subsequently left stand-

ing in a corner of the

airfield awaiting further

developments. But unlike

other out-of-use planes, it

was not their destiny to rust

away in so-called aircraft

cemeteries or at remote air-

fields. Instead, Belgium’s

Galloo Recycling Group has

recycled the two aircraft.

In early December, the

Cargo Queens of the Skies

– each weighing 140 tonnes – were cut

and torn into pieces, for which task

Galloo employed a Hitachi Zaxis 470

LC3 with a Labounty MSD shear, a

Hitachi Zaxis 470 LC with a Labounty

90 shear and a Kobelco E235 with a

Verachtert sorting grab.

The dismantling of two cargo planes

on the tarmac near the West Flanders

city of Ostend is not something Galloo

does every day. ‘The breaking of air-

planes is highly unusual here in Bel-

gium,’ says Jan Vandeputte, one of the

three managing directors at Galloo. ‘It

will probably take years before we will

dismantle the next airplane onsite.’

Help from Rolls Royce

Galloo’s dismantling efforts repre-

sented the second stage of the recov-

ery process. ‘First of all, the engines

were removed by Rolls Royce,’ explains

Vandeputte. ‘Still-usable system equip-

ment and instruments which can serve

as spare parts were also removed. In a

second step, the kerosene tanks were

carefully vented to avoid any risk of

explosion.’ Moreover, the hazardous

materials, lubricants and cooling fl uids

were removed by specialist companies

on behalf of Galloo NV. ‘The hazardous

materials are not a problem,’ states

Vandeputte. ‘As lists of harmful sub-

stances are obligatory in the aviation

industry, we know in advance where

we will find hazardous elements.’

Radioactive sources, for example.

‘These are going to be removed and

then stored in a controlled manner,’ he

says. ‘We have to report it to the Bel-

gian Federal Agency for Nuclear Con-

trol (FANC).’

After the shears had done their work,

the various pieces were

transported to Gal-

loo’s headquarters at Menen in Belgium

where they are being shredded and the

ferrous, non-ferrous and plastics ingre-

dients segregated. ‘We can separate

and granulate polypropylene, polyeth-

ylene, polystyrene, ABS and PPTALCUM,’

notes Vandeputte. The plastics recovered

by Galloo will be used by, among others,

the automotive industry.

Easier to dismantle

It seems that cargo planes are an

easier proposition for the dismantler.

‘Unlike in passenger aircraft, there are

no seats, windows or other non-metals

which have to be separated from the

metals,’ explains the Galloo managing

director. ‘Because we are dealing with

cargo aircraft, it is to be expected that

we will recover mostly aluminium, but

also wood, stainless steel and iron.’

Standing in front of the two heavy-

weight hulks, it is obvious that they are

proving a bountiful source of secondary

raw materials. According to Galloo, a

recycling level of plus or minus 90% will

be achieved, making this a fi nancially

positive exercise for the company.

A I R C R A F T R E C Y C L I N G By Mareike Kuhn

How Galloo is treating two cargo planes

Inch by inch, Galloo has recycled the two aircraft.

RI-1-2014-Galloo-Aircraft.indd 27 29-01-14 14:54